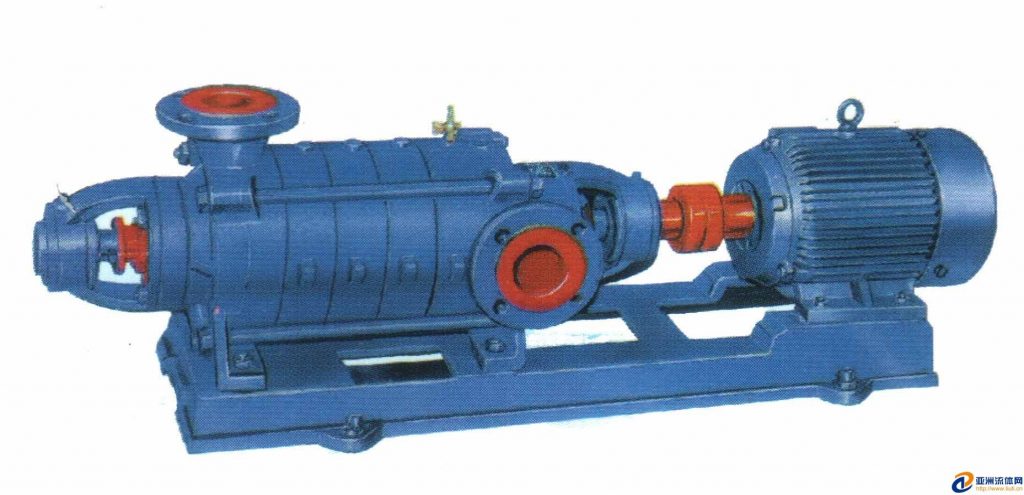

Multistage centrifuge pump consists mainly of stator, rotor, bearing and shaft seal.

1. The stator part of the multi-stage pump is mainly composed of the suction segment, middle segment, spitting segment and guide blade, etc. The tension bolts shall be clamped together to form the workshop. D type multistage pump pump general level inhalation, vertical up out; The inlet and inlet of the pump are vertical upward when used for water injection. The DG type multi-stage pump and inlet are all vertical.

2. The rotor part of the multi-stage pump is mainly composed of shaft, impeller, balance disk and axle sleeve. The axial force is balanced by the balance plate.

3. Multi-stage centrifuge pump bearing is mainly composed of bearing body, bearing and bearing pressure cover. The bearing is lubricated with grease or thin oil.

4. The multi-stage pump shaft seal is sealed with soft packing, mainly composed of the sealing letter body, packing and water retaining ring of the water inlet section and the end cover. D type multistage pump water sealing water comes from the pressure water in the pump. DG multi-stage pump water seal water is derived from external water supply.

5. The multi-stage pump rotary pump is driven directly by the original motive through the elastic coupling. From the original motive end of the pump, the pump is rotated clockwise in the direction of D, the DG stage multistage pump pump is a horizontal single-suction multi-stage centrifugal pump. For conveying clear water (with a quality less than 1%, particle less than 0.1mm) or physical chemistry similar to other liquids. Type D medium temperature is less than 80 ℃, the multistage pump pump is suitable for the mine drainage, oil field water injection, factories and cities, drainage, etc. The pump USES different materials according to the corrosive effect of the medium. Medium temperature is less than 105 ℃, the DG type pump are suitable for all kinds of boiler feed water.

What is the difference between a multi-stage pump and a single-stage pump?

1. Singlestage centrifuge pump is a pump with only one impeller, with a maximum lift of 125 meters;

2. Multi-stage pump is a pump with two or more impeller and the maximum lift can exceed 125 meters. Multistage pump in single-stage pump need must match two levels of motor cases, can be level 4 motor by increasing the number of impeller, which can improve the service life of the pump and reduces the noise, but relative single pump multistage pump maintenance must be a little difficult.

3, in the actual need to lift pump is less than 125 m, according to the pump room area, pump prices (general price is a little bit higher than the single stage pump multistage pump), factors such as comprehensive consideration, the single stage or multistage pump to use.

With the improvement of the technology, the pump of single stage impeller can raise the pump speed to lift the pump’s lift, but instead of the multi-stage pump, it is only a little more expensive.