AODD Air Operated Double Diaphragm Pump Performance Range:

AOD/AODD Air Operated Double Diaphragm Pump and EOD/EODD Electric Double Diaphragm Pump, manufactured by KEMAI Industrial Pump Co., LTD., is used for delivering high-viscosity, volatile, flammable, toxic liquid, such as: pulp, juice, milk, paint, cement, sewage with grain, molasses, glue, flour, dust, etc. This pump can be said to be an all-purpose pump.

Performance range: diameter: 3/8 inch, 1/2 inch, 3/4 inch, 1 inch, 1-1/4 inch, 1-1/2 inch, 2 inch, 2-1/2 inch, 3 inch, 4 inch, 5 inch; Flow rate: 12.8L/min~480L/min; Head: 40 m ~ 70 m; Pressure: 4 bar to 7 bar. Fluid Contact Parts: Cast steel, nodular cast iron, Aluminum alloy, pp, Stainless steel 304, Stainless steel 316, Stainless steel 316L, PVDF, PTFE.

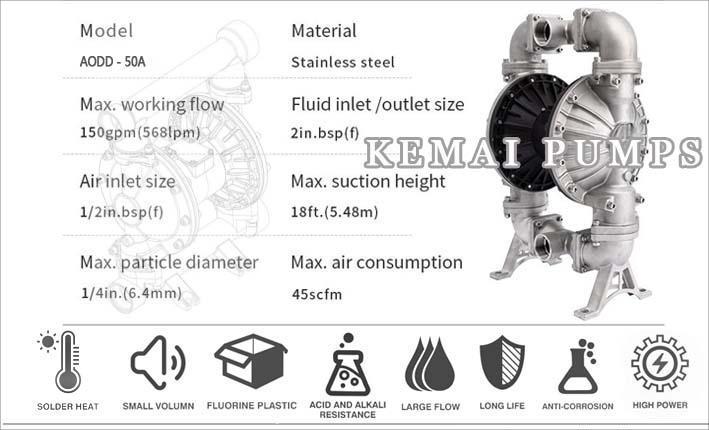

AODD Air Operated Double Diaphragm Pump Data Sheets:

| Specifications | AODD-50A |

| Max.Flow | 150 gpm (568 lpm) |

| Max.Working Pressure | 120 psi (0.84 Mpa,8.4 bar) |

| Fluid Inlet Size | 2 in.bsp (f) |

| Fluid Outlet Size | 2 in.bsp (f) |

| Air Inlet Size | 1/2 in.bsp (f) |

| Max.Suction Height(dry suction) | 18 ft. (5.48 m) |

| Max.Permitted Grain | 1/4 in. (6.4 mm) |

| Max. Air Consumption | 45 scfm |

| Every Reciprocating Flow | 1.03 gal. (3.90 L) |

| Max. Reciprocating Speed | 145 cpm |

| Pump body structure | Stainless steel 304/316/316L. |

AODD Air Operated Double Diaphragm Pump Main USES:

- All kinds of highly toxic, flammable and volatile liquids.

2. all kinds of strong acid, strong base, strong corrosive liquid.

- Medium with high temperature can be transported to 150℃.

4. as a variety of filter press front stage pressure feeding device.

- Hot water recovery and circulation.

- Loading and unloading of tankers, terminals and oil products.

7. Pump pickle jam, mashed potatoes, chocolate, etc.

8. pump paint, gum, pigment adhesive.

9. all kinds of porcelain glaze slurry, cement grouting, mortar, mud.

10. all kinds of rubber latex, organic solvents, fillers.

- Drain sewage and remaining oil from the bunker by pump for tanker barge clearance.

12. hops and baking powder pulp, syrup, molasses.

- Pump and suck sewage and sediment from mines, tunnels, tunnels and sewers.

- Suction of various special media.